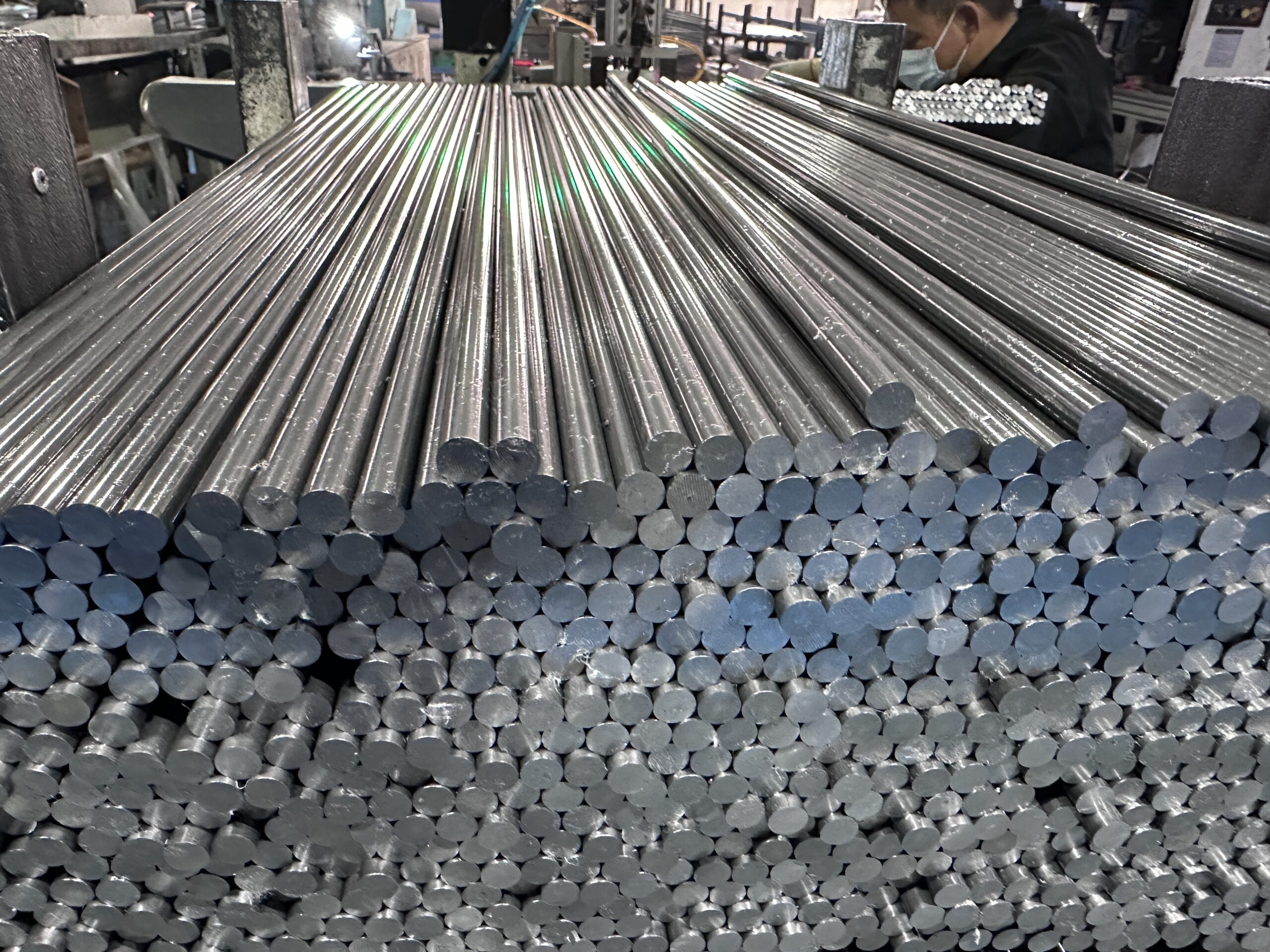

In precision machining, one truth never changes: a single defective bar can ruin an entire production batch. You might convince one customer, but you can never hide defects from the machining process itself. When stainless steel bars contain micro cracks, uneven structure, or unstable dimensions, the result is tool breakage, surface defects, and costly rework. This is exactly why 416F stainless steel bars are widely trusted in automatic lathes and Swiss-type machining.

The Real Cost of Hidden Cracks in Stainless Steel Bars

Micro cracks as small as 0.1 mm are often invisible to the naked eye. However, during high-speed machining, these cracks quickly turn into fracture points. Once a bar fails during processing, the consequences are serious. Scrap rates increase, tools wear faster, and production schedules get delayed.

For manufacturers running automatic lathes or Swiss machines, material consistency is not optional. Every bar must pass strict inspection before entering production. That is why high-quality 416F stainless steel bars go through full-length crack inspection, ensuring defects cannot hide.

What Makes 416F Stainless Steel Different

416F is a free-machining martensitic stainless steel. It is specially designed for applications where machinability, chip control, and dimensional accuracy matter more than extreme corrosion resistance. Compared with standard stainless steels, 416F offers smoother cutting behavior and more predictable performance on high-speed machines.

Chemical Composition of 416F Stainless Steel

| Element | Typical Content (%) | Role in Performance |

|---|---|---|

| Carbon (C) | ≤ 0.15 | Maintains strength without brittleness |

| Chromium (Cr) | 12.0–14.0 | Provides basic corrosion resistance |

| Sulfur (S) | 0.15–0.35 | Improves chip breaking and machinability |

| Manganese (Mn) | ≤ 1.25 | Enhances toughness |

| Silicon (Si) | ≤ 1.00 | Improves structural stability |

| Phosphorus (P) | ≤ 0.06 | Controlled for cleanliness |

| Iron (Fe) | Balance | Structural base |

The controlled sulfur content is the key reason 416F performs so well on automatic machines. It allows chips to break cleanly, reducing tool load and preventing chip entanglement.

Precision That Reduces Rework

In high-volume machining, tolerance stability directly affects cost. When bar diameter fluctuates, operators must leave extra machining allowance, which increases cycle time and material waste.

High-quality 416F stainless steel bars can achieve tight dimensional tolerance up to -0.02 mm, allowing direct machining without reserving extra stock. This means:

-

Shorter machining cycles

-

Less tool wear

-

Lower scrap rates

-

No repeated adjustments

For Swiss-type lathes, where material passes through guide bushings, diameter consistency is especially critical. Stable tolerance ensures smooth feeding and vibration-free cutting.

Smooth Chip Flow Means Stable Production

One of the most common problems in automatic machining is poor chip control. Long, sticky chips wrap around tools and parts, causing surface damage or machine stoppage.

416F stainless steel solves this problem naturally. Thanks to its optimized sulfur content and uniform microstructure, chips break easily and flow away from the cutting zone. Operators no longer need to constantly stop machines to clear chips.

This is why many shops report that switching to 416F stainless steel bars significantly reduces downtime and improves overall efficiency.

Typical Applications of 416F Stainless Steel Bars

416F stainless steel bars are widely used in parts that require high machining efficiency and dimensional stability, such as:

-

Precision shafts and pins

-

Valve components

-

Hydraulic fittings

-

Fasteners and connectors

-

Instrument parts

-

Small mechanical components produced on Swiss lathes

These parts often require consistent surface finish, stable dimensions, and repeatable machining behavior across large batches.

Quality Control That Makes the Difference

At Tongyi Metal, quality control is not just about meeting standards—it is about preventing problems before they happen. Each 416F stainless steel bar undergoes:

-

Full-length crack detection

-

Dimensional inspection for tolerance consistency

-

Surface quality checks

-

Batch traceability

This approach ensures that even micro cracks below 0.1 mm cannot pass through unnoticed. When bars reach the machining floor, operators can focus on production rather than troubleshooting material issues.

Why Consistency Matters More Than Marketing

A single bar might pass visual inspection, but machining never lies. When hundreds or thousands of parts are produced, only truly stable material survives the test. That is why manufacturers who rely on automatic lathes and Swiss machining continue to choose 416F stainless steel bars with proven inspection and process control.

If you are facing frequent rework, tool breakage, or unexplained scrap, the root cause is often the material—not the machine or operator.

416F stainless steel bars are trusted in automatic and Swiss-type machining because they deliver what production lines truly need: crack-free structure, smooth chip flow, tight tolerance, and stable performance. With proper inspection and precision control, they help manufacturers reduce rework, protect tools, and maintain consistent output.

If you are evaluating materials for high-speed machining and want fewer surprises on the shop floor, 416F stainless steel bars are worth serious consideration.