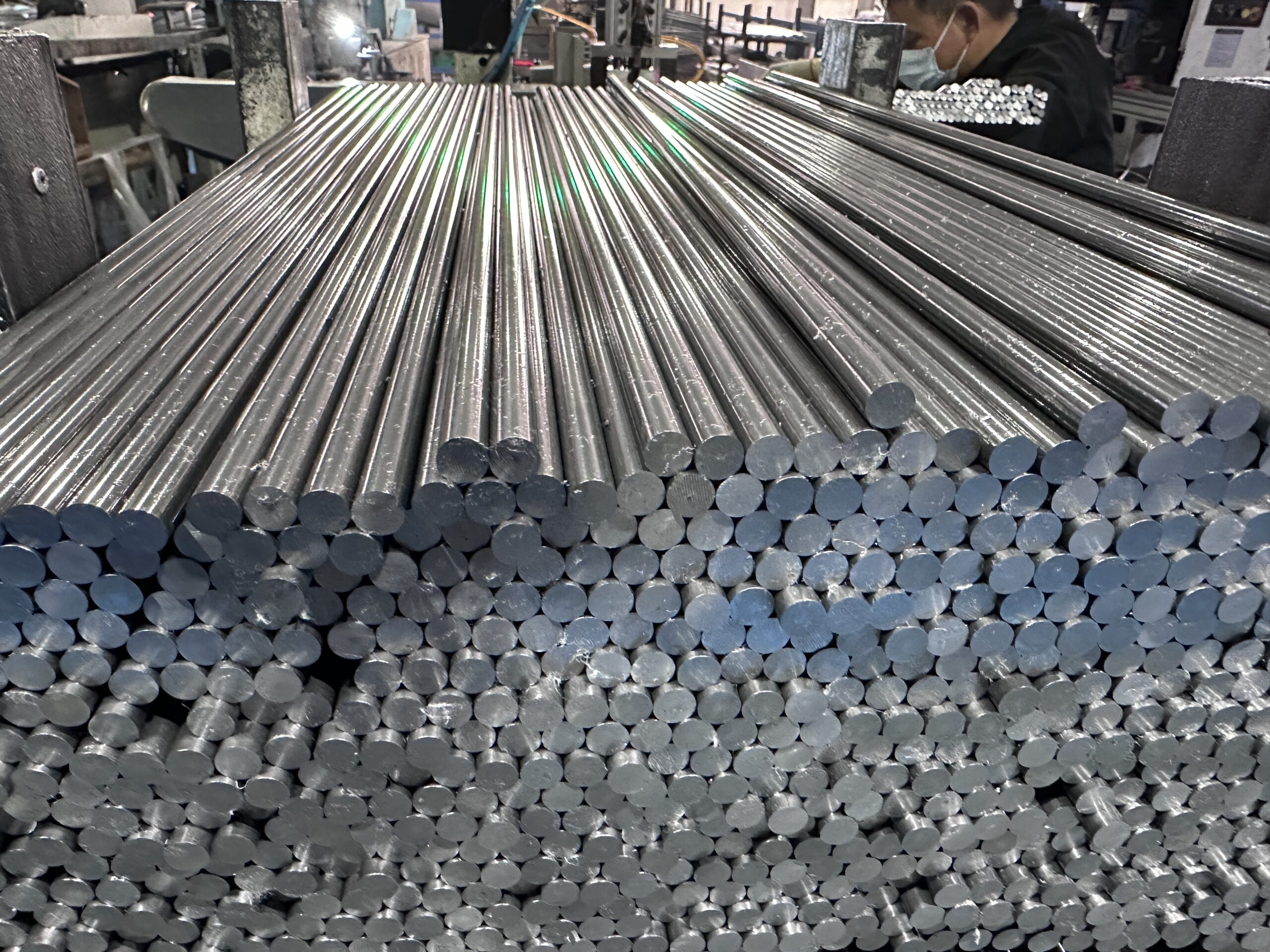

Applications of 304 Stainless Steel Rods in Food Processing

304 stainless steel is one of the most commonly used materials in the food processing industry due to its excellent corrosion resistance, hygiene properties, and mechanical strength. In this article, we will explore the key benefits, specific applications, and why 304 stainless steel rods are essential for food processing equipment.

Why 304 Stainless Steel is Ideal for Food Processing

304 stainless steel offers several key properties that make it an ideal choice for food industry applications:

| Property | Benefit in Food Processing |

|---|---|

| Corrosion Resistance | Prevents contamination and extends equipment lifespan |

| Non-Toxic & Hygienic | Does not react with food or release harmful chemicals |

| High Strength & Durability | Withstands mechanical stress and wear |

| Ease of Cleaning | Smooth surface prevents bacterial growth |

| Heat & Chemical Resistance | Handles high temperatures and cleaning agents |

These characteristics ensure that food production remains safe, efficient, and compliant with industry regulations.

Common Applications of 304 Stainless Steel Rods in Food Processing

304 stainless steel rods are widely used in various food processing applications:

| Application | Role of 304 Stainless Steel Rods |

|---|---|

| Food Mixing Equipment | Provides durability and hygiene in mixing components |

| Conveyor Systems | Used for shafts, rollers, and framework |

| Food Storage Tanks | Ensures non-reactivity and long-term preservation |

| Cutting & Grinding Machines | Offers sharpness retention and corrosion resistance |

| Baking & Cooking Equipment | Handles high temperatures and repeated use |

Case Study: Using 304 Stainless Steel Rods in a Food Factory

A large-scale food processing plant required an upgrade to its conveyor system. The previous carbon steel shafts corroded quickly due to frequent exposure to cleaning chemicals and food acids. By switching to 304 stainless steel rods, the plant achieved:

- Increased Equipment Longevity: No rusting, reducing maintenance costs.

- Improved Hygiene Standards: Smooth, easy-to-clean surfaces met food safety regulations.

- Enhanced Operational Efficiency: Stronger rods reduced machine downtime and breakdowns.

Conclusion

304 stainless steel rods are a crucial material for the food processing industry, offering unmatched hygiene, durability, and safety. Investing in high-quality stainless steel ensures better equipment performance and compliance with strict food safety standards.

Looking for premium 304 stainless steel rods for food processing applications? Contact us today for expert advice and high-quality materials!