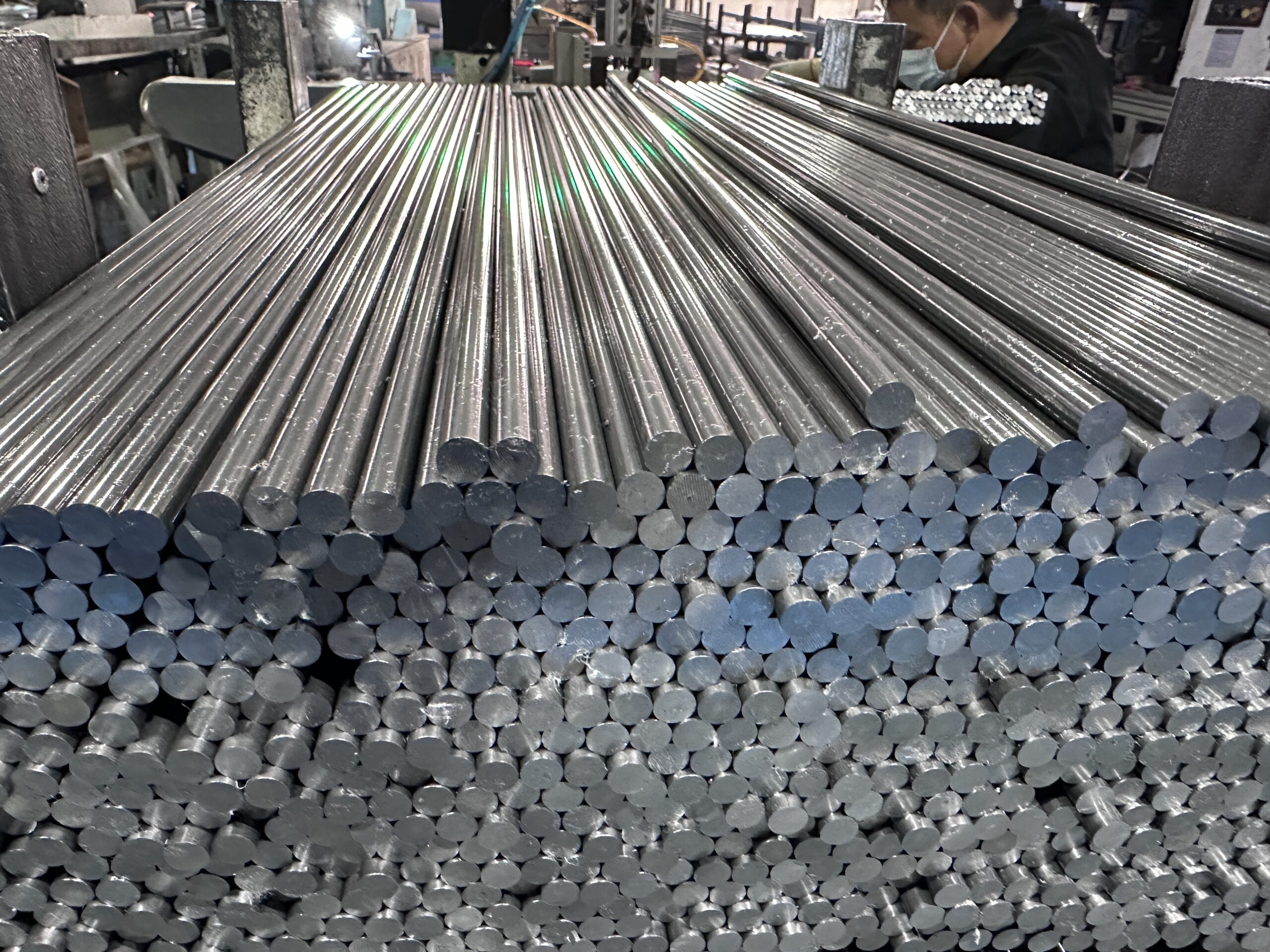

316L and 304 stainless steel bars are both popular choices in industries requiring durability and corrosion resistance. While they share similarities, their differences make them suitable for specific applications.

1. Chemical Composition

316L contains molybdenum, enhancing its resistance to chlorides and acidic environments. 304 lacks molybdenum but has slightly higher chromium content.

2. Corrosion Resistance

316L offers superior resistance to pitting and crevice corrosion, especially in marine or chemical processing environments. 304 is suitable for general environments but may corrode faster in high-chloride areas.

3. Strength and Hardness

Both grades have similar tensile strength, but 316L retains better mechanical properties at high temperatures.

4. Applications

-

316L: Marine equipment, chemical processing, medical devices

-

304: Kitchen equipment, food processing, architectural components

Comparison Table

| Property | 316L Stainless Steel Bar | 304 Stainless Steel Bar |

|---|---|---|

| Molybdenum Content | 2-3% | 0% |

| Corrosion Resistance | Excellent (especially in chlorides) | Good, less effective in chlorides |

| Tensile Strength (MPa) | 515 | 520 |

| Temperature Resistance | Better at high temperatures | Good, but less than 316L |

| Typical Applications | Marine, chemical, medical | Food, kitchen, architecture |

Choosing between 316L and 304 stainless steel bars depends on your environment and performance requirements. For marine or chemical use, 316L is preferred; for general indoor and food-related uses, 304 is cost-effective. Tongyi Metal provides both grades with strict quality standards to meet diverse industrial needs.