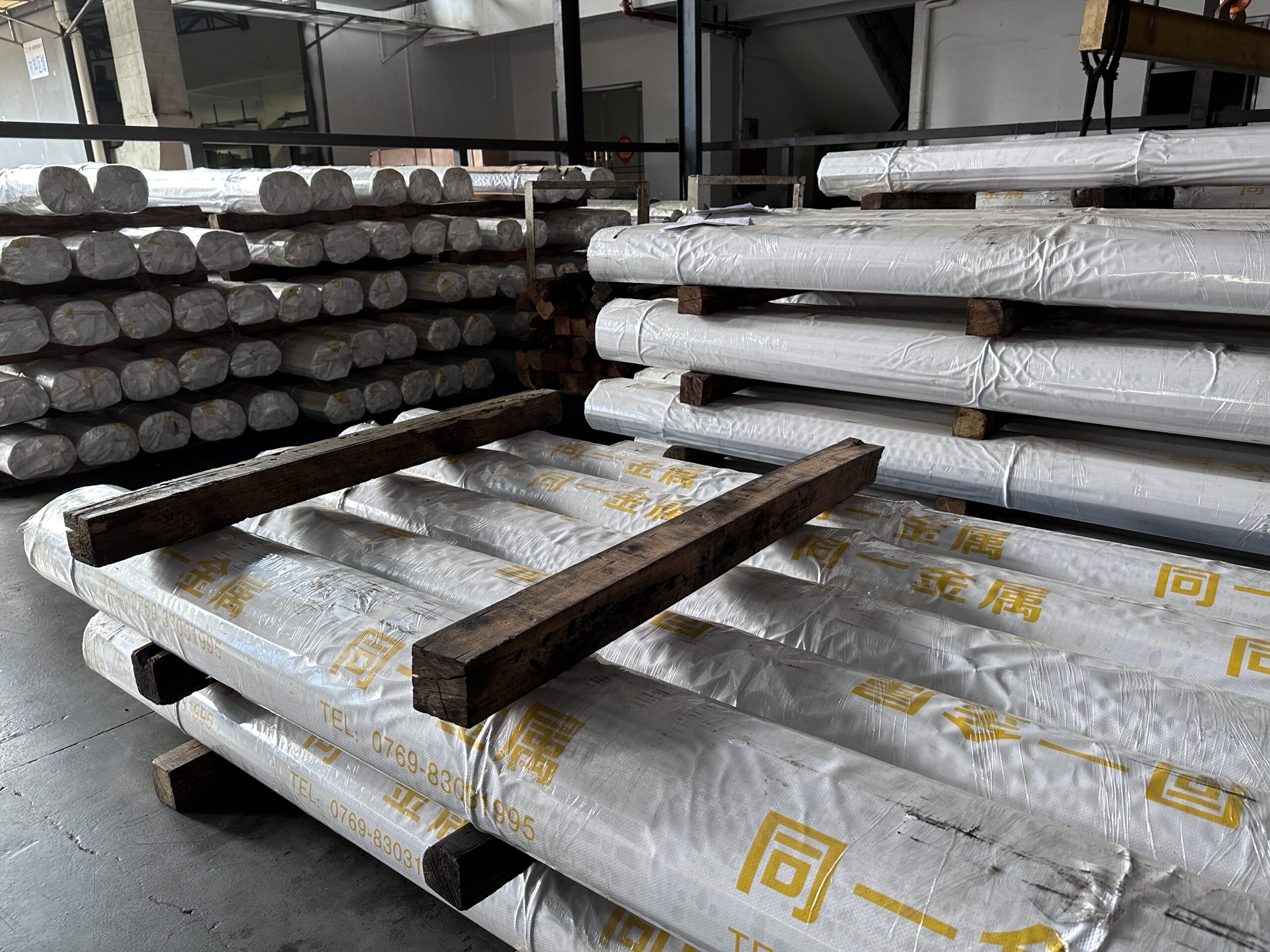

When it comes to building advanced robots, material selection plays a critical role in determining performance, durability, and long-term stability. Among various stainless steel grades, 17-4PH stainless steel bar has gained significant popularity in the robotics industry thanks to its unique combination of high strength, corrosion resistance, and heat-treatable properties. This article explores how 17-4PH stainless steel is applied in robotics, why it is chosen, and some typical application cases.

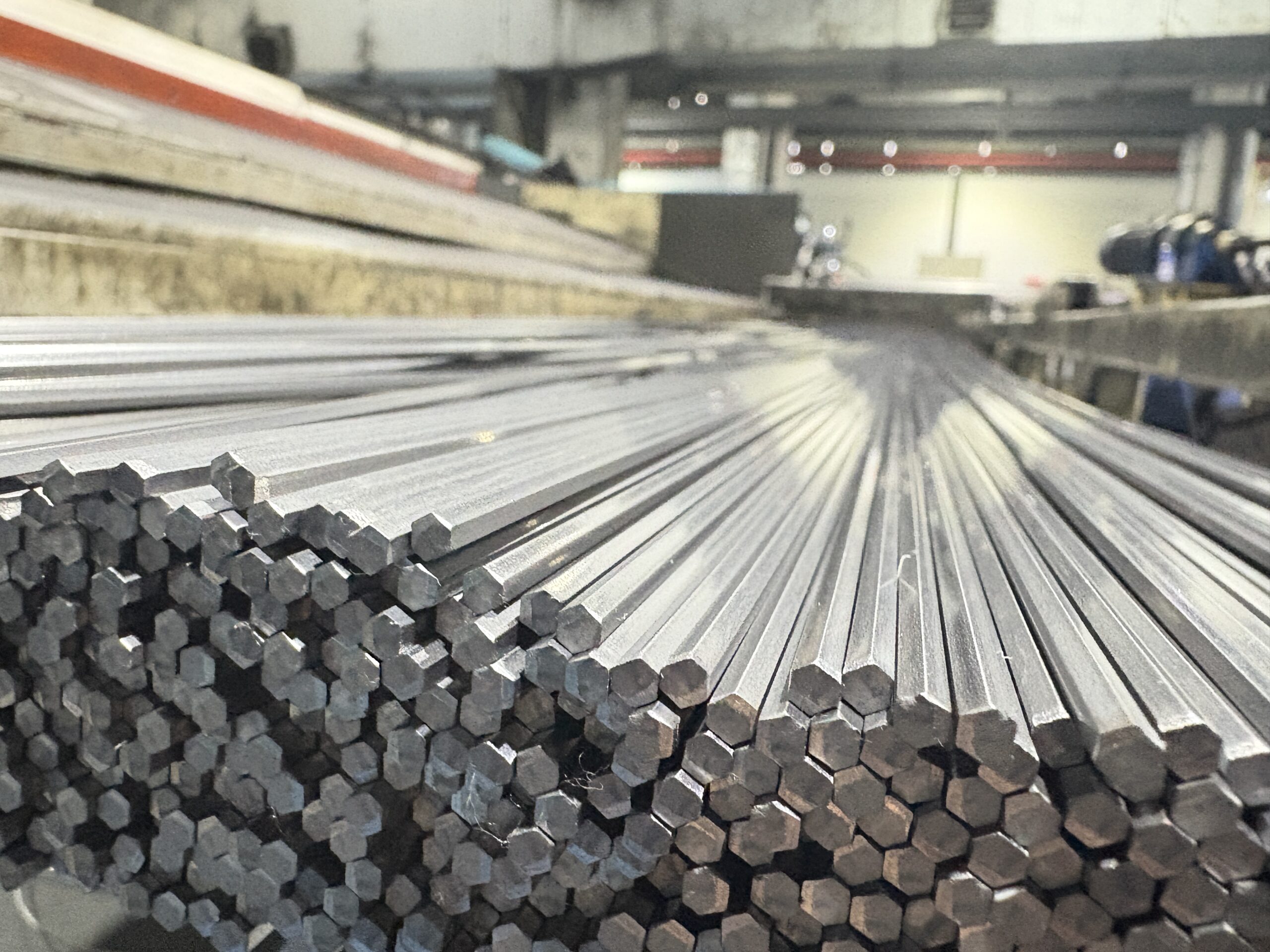

Key Features of 17-4PH Stainless Steel

17-4PH (also known as 1.4542 or UNS S17400) is a precipitation-hardening martensitic stainless steel. Its most distinctive feature is that it can be strengthened through heat treatment to reach very high hardness levels without compromising corrosion resistance.

| Property | 17-4PH Stainless Steel |

|---|---|

| Tensile Strength | Up to 1310 MPa (after heat treatment) |

| Hardness (HRC) | 35–44 HRC |

| Corrosion Resistance | Comparable to 304 stainless steel |

| Heat Treatment Response | Excellent |

| Machinability | Moderate |

These properties make it highly suitable for robotic components that require strength and resistance to harsh working environments.

Why Robots Need 17-4PH Stainless Steel

-

Strength-to-Weight Balance

Robotic arms, joints, and structural frames must withstand repeated motion, vibration, and load-bearing conditions. 17-4PH offers high strength while maintaining a relatively lower density compared to tool steels. -

Resistance to Corrosion

Industrial robots often work in humid, chemical, or outdoor environments. 17-4PH provides adequate protection against corrosion, extending the service life of critical components. -

Heat-Treatable for Performance Tuning

Engineers can adjust the hardness and mechanical strength of 17-4PH bars through different heat treatments (H900, H1025, etc.), tailoring materials for specific robotic tasks. -

Dimensional Stability

Robots require precision. 17-4PH maintains stability under stress and temperature variations, ensuring high-accuracy movements.

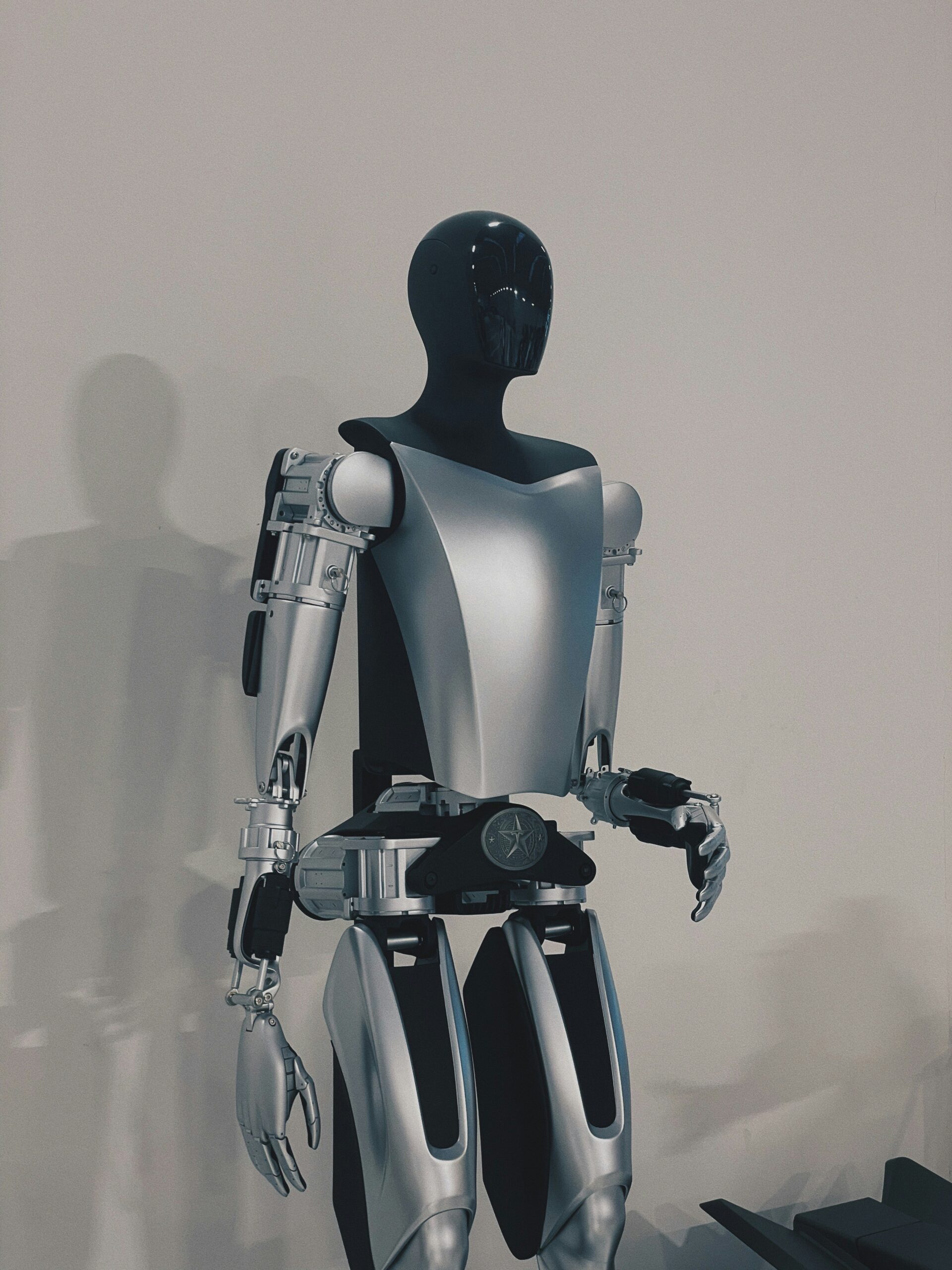

Application Cases in Robotics

-

Robotic Arm Joints

High-strength bars are machined into rotating joints and connectors, where precision and durability are essential. -

Actuator Components

17-4PH stainless steel bars are used in parts that transfer motion, ensuring minimal wear under repetitive cycles. -

Robotic Structural Frames

Support frames that carry load benefit from its combination of toughness and corrosion resistance. -

Medical and Service Robots

In robots used for healthcare or service industries, 17-4PH provides biocompatibility and hygiene-friendly surfaces.

Industry Example

A well-known robotics company specializing in automated welding robots reported that switching from 304 stainless steel to 17-4PH for their arm joints increased operational lifespan by 40%. The material’s superior hardness and fatigue resistance reduced the need for frequent maintenance and downtime.

17-4PH stainless steel bars provide the perfect balance of strength, hardness, and corrosion resistance, making them a material of choice for robotics. From industrial manipulators to medical robots, this stainless steel grade ensures long-term durability and reliability. For manufacturers aiming to improve robotic efficiency and service life, 17-4PH is one of the most suitable options available.