When it comes to high-strength shaft parts, precision, surface quality, and durability are everything. GCr15 grinding bars—also known as bearing steel bars—have become the industry standard for precision shafts and high-load components. Their unique chemical composition and controlled heat treatment make them the top choice for demanding mechanical applications.

Key Chemical Composition of GCr15

| Element | Composition (%) | Function |

|---|---|---|

| C (Carbon) | 0.95–1.05 | Provides hardness and wear resistance |

| Cr (Chromium) | 1.30–1.65 | Enhances hardenability and corrosion resistance |

| Mn (Manganese) | ≤ 0.40 | Improves toughness |

| Si (Silicon) | ≤ 0.35 | Strengthens and improves elasticity |

| P (Phosphorus) | ≤ 0.025 | Controlled for improved machinability |

| S (Sulfur) | ≤ 0.025 | Controlled for cleanliness |

This balance of elements gives GCr15 its signature combination of high hardness, wear resistance, and dimensional stability—traits essential for shaft components that endure heavy stress and friction.

Mechanical Properties of GCr15

| Property | Value (After Quenching & Tempering) |

|---|---|

| Hardness (HRC) | 58–62 |

| Tensile Strength (MPa) | ≥ 1080 |

| Yield Strength (MPa) | ≥ 850 |

| Elongation (%) | ≥ 8 |

| Impact Toughness (J/cm²) | ≥ 15 |

After proper heat treatment, GCr15 bars maintain exceptional surface hardness and uniform internal structure. This makes them ideal for precision grinding and finishing, ensuring shaft straightness and stability even under high loads.

Why GCr15 Is Perfect for High-Strength Shaft Applications

1. Excellent Dimensional Stability

Shaft parts often require micron-level accuracy. GCr15 maintains stable geometry after machining and heat treatment, minimizing deformation and ensuring perfect balance.

2. High Wear Resistance

Its fine martensitic structure and uniform carbide distribution provide outstanding wear resistance—vital for rotating parts exposed to constant friction.

3. Superior Fatigue Strength

The high carbon and chromium content increase fatigue life, enabling longer operation cycles with less maintenance.

4. Consistent Hardness and Surface Quality

GCr15 grinding bars achieve hardness between HRC 58–62, ideal for applications like motor shafts, spindles, and precision transmission components.

Typical Applications of GCr15 Grinding Bars

-

Precision shafts in automotive and industrial machinery

-

Bearing races and rollers

-

High-speed spindle components

-

Hydraulic pump shafts and precision drive systems

-

Aerospace mechanical linkages

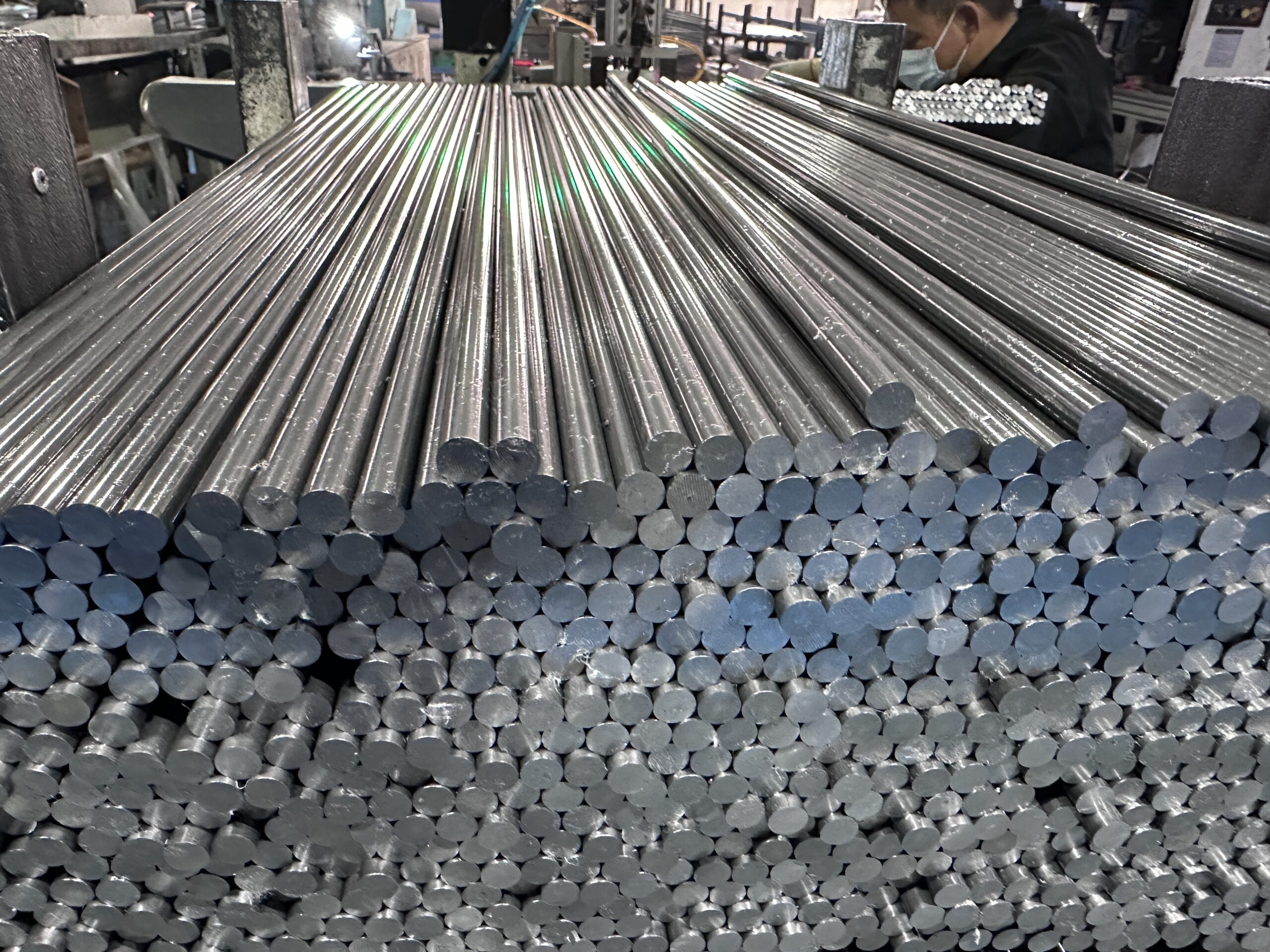

Why Choose Tongyi Metal’s GCr15 Grinding Bars

At Tongyi Metal, every GCr15 grinding bar undergoes strict heat treatment and dimensional control. The bars feature:

-

Tight tolerance: roundness ≤ 0.005 mm, straightness ≤ 0.02 mm

-

Uniform hardness: stable HRC 58–62 throughout the section

-

Polished surface: Ra ≤ 0.4 for smooth, ready-to-machine finish

With advanced drawing and grinding equipment, Tongyi Metal ensures stable performance and superior consistency batch after batch—making them a reliable partner for high-precision shaft manufacturing.

Conclusion

GCr15 grinding bars are the backbone of high-precision shaft manufacturing. Their hardness, toughness, and dimensional accuracy make them indispensable in automotive, aerospace, and industrial machinery applications. Choosing Tongyi Metal’s GCr15 precision grinding bars means choosing reliability, consistency, and performance your parts can depend on.