In precision manufacturing, straightness is one of the most vital performance indicators for stainless steel bars. For 316L stainless steel bars used in CNC machining, automotive shafts, or medical components, maintaining a straightness deviation within 0.02mm—known in China as “2丝”—requires advanced processes, high-accuracy equipment, and strict quality control. Tongyi Metal’s precision production system ensures every bar meets the most demanding standards for dimensional stability and consistency.

1. Material Advantages of 316L Stainless Steel

316L stainless steel is a low-carbon austenitic alloy that combines corrosion resistance, strength, and ductility. The addition of molybdenum enhances resistance to pitting and crevice corrosion, while the low carbon level prevents carbide precipitation during welding. These metallurgical properties provide exceptional dimensional stability and make 316L ideal for high-precision rods, shafts, and structural parts that require both toughness and precision.

2. Importance of Maintaining 0.02mm Straightness

Straightness defines how close a bar is to an ideal straight line along its full length. In machining or assembly, even a slight bend can cause tool deviation, component misalignment, or vibration. Maintaining ≤0.02mm straightness ensures:

-

Consistent dimensional accuracy during CNC turning or grinding.

-

Reduced vibration and extended tool life.

-

Perfect fit and alignment in high-precision assemblies.

-

Improved overall stability and performance of mechanical systems.

3. Process Flow for Precision Straightness Control

Each production step affects the final straightness of 316L stainless steel bars. At Tongyi Metal, precision is achieved through meticulous process control—from billet preparation to final inspection.

| Process Stage | Description | Straightness Control Technique |

|---|---|---|

| Melting & Casting | High-purity raw materials are melted and cast into billets. | Controlled cooling and alloy purity verification. |

| Hot Rolling | Billets are shaped into rough bars. | Balanced temperature and rolling tension. |

| Annealing | Heat treatment removes internal stress. | Uniform furnace temperature ±5°C. |

| Cold Drawing | Refines diameter and surface precision. | Multi-stage drawing with stress-relief cycles. |

| Straightening | Corrects curvature and bowing. | Multi-roller straightening with precision monitoring. |

| Centerless Grinding | Ensures size accuracy and fine finish. | Real-time alignment and vibration control. |

| Laser Inspection | Verifies final geometry and deviation. | Automated laser scanning within 0.02mm tolerance. |

4. Advanced Straightening and Grinding Techniques

After cold drawing, the bar may retain residual stress that leads to minor bending. Tongyi Metal applies advanced multi-point roller straightening, where rollers adjust curvature through micro-bending correction. Then, the bar undergoes centerless grinding with vibration-free systems to achieve both surface finish and straightness precision. Real-time laser feedback ensures the final deviation stays within 0.02mm across the entire length.

5. Inspection and Quality Verification

Straightness inspection is performed using both mechanical and optical systems. V-block and dial gauge measurements provide quick verification, while laser measurement systems and coordinate measuring machines (CMM) ensure full-length accuracy.

Inspection Steps:

-

Place bar on precision V-blocks.

-

Rotate 360° and measure deviation with a dial gauge.

-

Perform laser scanning for full-length curvature mapping.

-

Record data in the Mill Test Certificate (MTC) for traceability.

All 316L bars undergo 100% straightness inspection before packaging to guarantee performance consistency in customer applications.

6. Factors Affecting Straightness

Several technical and environmental factors influence the final straightness of 316L stainless steel bars:

-

Residual Stress: Released through controlled annealing and cooling.

-

Uneven Cooling: Prevented with precise temperature management.

-

Handling and Storage: Improper stacking can bend bars; supported racks are used.

-

Machining Stress: Controlled by optimizing feed rate and clamping pressure.

7. Applications Requiring 0.02mm Straightness

316L stainless steel bars with ultra-high straightness are widely used in:

-

Automotive manufacturing: door lock shafts, precision pins, and transmission rods.

-

Medical equipment: surgical rods, implant guides, and precision tools.

-

Aerospace engineering: actuator rods and control shafts.

-

Robotics and automation: linear shafts and motion components.

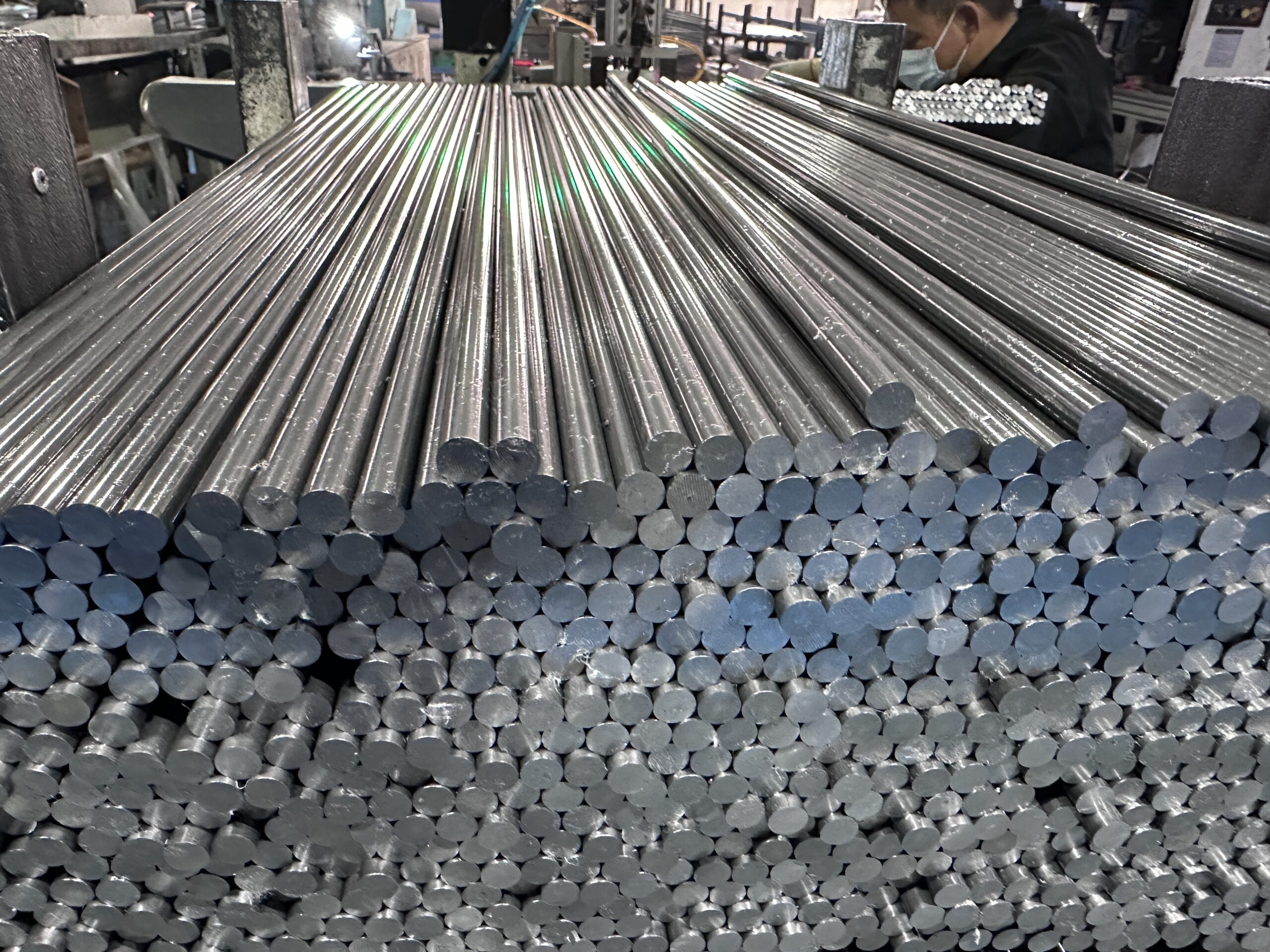

8. Why Choose Tongyi Metal

Tongyi Metal specializes in precision stainless steel production with a focus on straightness and stability. Our advantages include:

-

Over 60 production lines for precision stainless bars.

-

Automated straightening and centerless grinding equipment.

-

Laser inspection systems ensuring 0.02mm straightness tolerance.

-

ISO-certified quality management and complete MTC documentation.

Achieving 0.02mm straightness in 316L stainless steel bars requires advanced material control, precision equipment, and strict inspection standards. At Tongyi Metal, every bar is engineered for consistency, performance, and long-term reliability. Whether for automotive, medical, or aerospace use, our precision 316L stainless steel bars provide unmatched accuracy and stability for your most demanding applications.